Secure Garment Disposal

Protect your Brand

Our garment collection and shredding service has been designed to ensure that your brand is protected though the secure disposal of branded garments.

Unfortunately, today Staff uniforms and Branded clothing is highly valuable to others, no longer is printed and electronic data the only source of valuable information. Failure to dispose of these garments correctly may result in damage of brand reputation and unauthorised access to restricted areas which may result in a breach of the Data Protection Act.

Hazchem’s secure collection and shredding service is the perfect solution to ensure that the necessary steps are taken to ensure that your business in protected. This is possible with our 100% traceable service.

Top 5 Reasons to Choose Us

Sustainable and Simple

Simple and easy, with great results. Here’s 5 great reasons to choose Greener Safety by Hazchem to manage this service on your behalf.

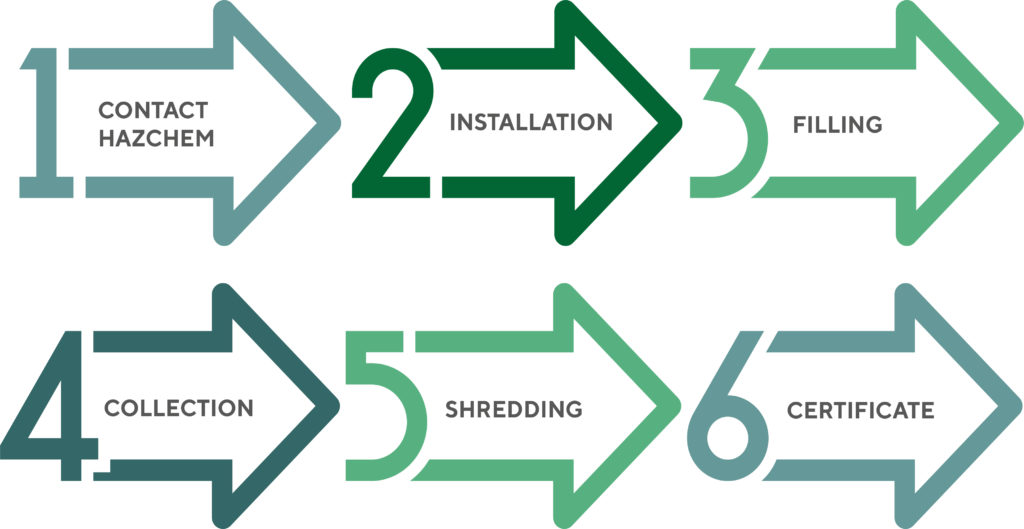

How does it work?

6 Steps to Certification

The first step is to contact us here at Hazchem and one of our team will help to discuss your needs and get you signed up to the service. call us on +44 (0)1280 841400 or email us sales@hazchemsafety.com

We will then arrange the one-off collection or weekly, monthly or 2-6 monthly collections, including the number of garment bins that you think will be required.

The bins will be delivered and positioned in a secure location for you to fill up with all your unused garments before your next scheduled collection date.

Once your garments are collected, they will then be shredded and recycled sustainably. At this point you will receive a Certificate of Destruction and an invoice will then be issued.

“Hazchem Safety’s Secure Garment Disposal Service has been a winner for us. It removes the headache of disposing of used garments AND we contribute to our Net Zero Goals”

The Process

Step by Step Process for Secure Disposal

Destruction is traceable via a secure audit trail throughout the whole process following the security shredding standards. Our high-capacity cross-cut shredding destruction system will shred in excess of 2 tons per hour. This is the beginning of the recycling process.

The shred is a cross-cut system so there is full security assured. No items can ever be reconstructed once they have been through the secure destruction process. Once the secure destruction of the waste material is complete, it is then baled into what is known as ‘mill-size’ bales and transported to the specialist mills we work in partnership with.

Working with Avena for your secure destruction process, you can be assured of guaranteed security and integrity yet benefit from the most ultimate environmentally sustainable package that can be offered in the marketplace.

Through extensive research and development, we have created the complete environmentally sustainable package. This has allowed us to eradicate the ‘recycling issue’ when destroying corporate workwear for brand security reasons. By working with many textile and recycling mills we have now managed to develop a strategy to recycle this fibre.

Once baled at the depot, the waste will then be exported to various specialist recycling mills and organisations around the world. The baled fibre material is then put through a process that splits the bales’, takes the shredded waste through various processes and finally stretches it into a fibrous material. This innovative material has a wide variety of uses including geotextiles, special papers and other innovative products.

Initially, the shredded waste is taken through a number of processes through various types of conveyors and finally stretched into a fibrous material. Custom-built machinery specifically designed for the whole process takes the shredded material in and then processes it into the ingenious fibre. The fibre is then compacted, then baled again, and at this stage, it is then ready for distribution to the end-users. The whole process is environmentally sustainable.

Some of the many materials we process are:

- Cotton

- Jute Sisal

- Acrylic Polyester

- Complex Blendings Thermoplastics

- Glass Fibre

Invest in our Future

Trusted by brands in the Energy Industry